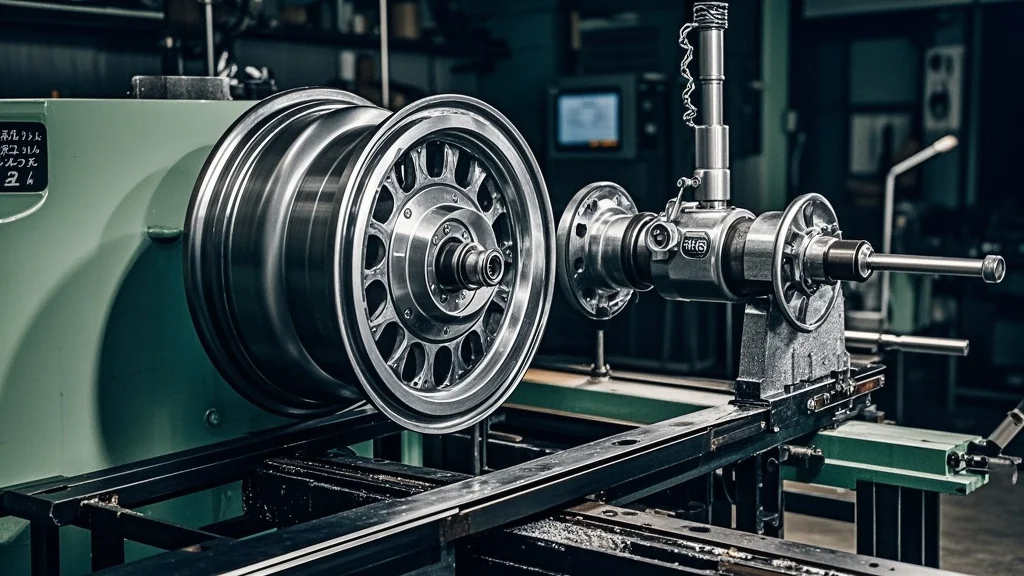

In the premium automotive aftermarket, Diamond Cut wheels have become a standard feature. However, curb rash remains the most common pain point for car owners. For repair shops, traditional manual sanding can no longer replicate the original factory finish. Integrating an automated Wheel Repair CNC Lathe has become the key to increasing service premiums and operational efficiency.

1. Why Your Workshop Needs a Professional Wheel Repair Machine?

- Factory-Quality Finish: Equipped with high-precision laser detection systems, these machines automatically scan the wheel profile to perfectly restore the original metallic diamond-cut texture—something manual labor simply cannot achieve.

- User-Friendly Operation: Modern repair lathes feature “One-Touch” automation. Even without deep programming expertise, technicians can complete scanning, optimization, and cutting within minutes via an intuitive touch-screen interface.

- High Return on Investment (ROI): The service fee for repairing a diamond-cut wheel is significantly higher than standard painting, while the operational cost per wheel is minimal. For shops with steady volume, the equipment investment can often be recovered within a few months.

2. Three Core Metrics for Choosing a Wheel Repair Lathe

- Scanning Precision & Speed: Prioritize machines equipped with non-contact laser probes. Compared to traditional physical probes, laser scanning is faster and eliminates the risk of scratching the wheel surface during the process.

- System Stability: An industrial-grade CNC control system ensures millimeter-level error control, maintaining consistency even during high-volume refurbishment tasks.

- Machine Structure: A Cast Iron Bed offers superior vibration dampening. This is crucial for eliminating vibration patterns during cutting and ensuring a mirror-like surface finish.

3. Digital Repair: Transforming Your Workshop

As the automotive service industry undergoes digital transformation, possessing automated repair capabilities allows your workshop to secure outsourcing contracts from insurance companies and high-end 4S dealerships. This is not just an equipment upgrade—it is a leap in competitive service positioning.